Troubleshooting and Repairing the

Mercedes-Benz 190D and 190E Tempmatic ACC Climate

Control System

by John

Cacavas,

© 2017.† Not to be copied without permission of the author.† But feel free to use this link.

Last updated May 2017.† If you have any comments or suggestions, or if I've got something not quite right, please feel free to contact me at jcacavas@gmail.com.†

I have written this article and added to it

over the years while troubleshooting my own 1985 190D 2.2.†††† It is a complex system, and I will focus

on the electronic and vacuum circuits, and will make the assumption that your

compressor is operational.

SOME

QUICK WORDS ON THE COMPRESSOR

There are several reasons why a compressor

might not turn on.† To test, select the

top button (max AC) and then the button with the two boxes on it, meaning the

center and side vents.††† The system must

pass several internal tests before the compressor comes on.

Recently my compressor stopped working, but I

noticed that it coincided with the failure of my tachometer.†† One of the internal tests is that the

compressor must be spinning at the same rate as the engine.† If anything prevents this, then no cold.† This includes oil on the belt, or belt

slippage of any kind, or in my case, a faulty engine RPM sensor.†† The system was told that the engine is not

spinning, but the compressor is, and it failed the test.† If you have a diesel and your tachometer is

not working, take a look at the RPM sensor.†

It is mounted on the engine bell housing, on the same side as the oil

level sensor, just a bit farther back.†

You can get to it by removing the front lower panel, as you would do

when changing your oil.†† Look a bit

farther back than the oil pan, on the bell housing, and it is a little black

thing with a wire on it which points straight up.† In my case, the wire was broken, and I was

able to take it out, cut away about a quarter inch of the black plastic

housing, and then solder some new leads onto the wire stubs.† I taped it up and now the tach works fine,

and once again the air conditioner works as it should.† If yours is bad and you canít fix it, they

can be had for about sixty dollars.†† The

other end of the wire terminates in a small connector located behind the

battery, under the leaf trap.

Sometimes the KLIMA relay (N6) can go

bad.††† Iíve never had this happen, but

be aware that it can.†† It controls the

air conditioner function.††† Pull out the

relay, and jumper pins 5 and 7.† If your

compressor has gas, then it should quickly cool down your car.†

If the evaporator temperature sensor opens,

then the air conditioner will not kick on either.

If the clutch slips on the compressor, due to

either dirt or a bad electrical connection, then the compressor will shut

off.†† This leads back to the concept of

dissimilar speeds of the engine and compressor.†† I heard that the reason why Mercedes added

the belly pan on this car is to keep the dirt and mud off the belt and causing

this from happening.† If your belly pan

is missing, you might want to get another one.

If your car has an overload relay, and the

fuse is bad or the contacts are dirty, the compressor may not work as it

should.††

If you find that the gas has leaked out of

your system, and you need a recharge, ask the shop to recharge the system and

add their special yellow/green dye.† Then

run the car with the A/C on for a few minutes, and then have them take a look

under the car with their black light.† If

there is a leak, it will show up in a very obvious way.† My recent leaks have been on the back side of

the compressor, and there are three o-rings which can cause the leak:† two are on the hose manifold, and there is a

third under the snap ring on the very center - the speed sensor.†† The compressor comes out easily.†† The shop may be tempted to do only the two

most visible ones, but insist they do the third as well.† You donít want to have to pull the compressor

any more than you have to.†† You may also

have bad hoses on the manifold.† You can

either buy a whole new manifold with hoses, or have new hoses put onto your old

manifold.† I now cover my hoses with

plastic tubing to keep oil from dripping on them and ruining them prematurely.

If your compressor comes on but makes a huge

amount of noise, or locks up, it is most likely shot.

VACUUM

PUMP TESTER WITH GAUGE: A

must-have tool for troubleshooting this system is a vacuum pump with gauge. I

own a Mityvac, and have been satisfied with it. It cost around $50 at a good

auto parts store. It will come in handy for other projects as well; a separate

accessory kit can also be purchased which allows for one-person brake bleeding.

Another necessary tool will be a good digital voltmeter, with some way of

piercing a wire to take a voltage reading through it. If your voltmeter can be

equipped with clips, you can make do by pushing a cork board pushpin through

the wire and then clipping onto it.

ELECTRIC

FAN AND ENGINE FAN TROUBLESHOOTING Ė

It seems that every few years, both fans stop working.† Oftentimes it is the red three pole

temperature switch, and the system is fairly easy to test.† The idea is that when the switch is heated by

the coolant to a certain temperature, the switch provides a path to ground and

the fans engage.† The double pole part is

for the engine fan clutch, and the single pole part is for the electric fan.†† To test Ė turn the ignition on, pull off the

double pole connector, and then use a wire jumper to bridge the two holes in

the connector.† You should hear a Ďclickí

as the clutch locks the fan to the crankshaft.†

To test the electric fan, remove the single pole connector from the

switch.† Use a jumper wire to connect the

hole in the connector to ground Ė any convenient place Ė engine block will

do.† The fan should roar to life.††† If both fans work as tested, then the

switch is likely bad.† They donít last

forever, and I have a suspicion they donít like to get wet.†† If one or the other fan does not engage when

tested, then the problem lies with the wires or the fan Ė probably the

wires.† They get hot and brittle over

time, and can easily break inside the connectors.† Give a gentle tug and see if the wire comes

out of the connector.† Remember there are

also connectors on the electric fan and the clutch, so check those ends

too.† I have had to repair the wires down

on the clutch (behind the engine fan).†

Connectors can be carefully opened, and new wire can be resoldered to the inside part.†

RADIATOR

FAN RATTLE - Recently, I noticed a

rattle coming from the front of my Mercedes 190D engine.† The usual culprits of alternator bearings and

noisy front belt shock absorber were ruled out, and then I began focusing on

the radiator fan / fan clutch assembly.††

I isolated the rattle by starting the engine when it was cold, which, as

long as the air conditioner is switched off, meant that the fan clutch was not

engaged.†† I was able to stop the

free-wheeling fan with a stick, (don't even try doing this with your fingers in

case the fan is energized) and once stationary, I found that I could make the

noise go away by wiggling the fan and holding it in certain positions.†† But - what was causing the problem?††† I removed the fan - one 13mm bolt in the

center of the fan - and cowling (two clips), and looked on the back of the removed

fan.† There is a center bearing, which

can obviously go bad, but there is also a metal ring, which is drawn up against

the magnetic fan clutch when it is energized.†

This metal ring is attached to the plastic fan with three strips of

flexible metal - springs - and in my case, the ring and the springs were no

longer solid, and indeed, I could reproduce the rattle by tapping on the metal

ring.†† I tried to make it better by

bending around with the ring and the spring, but this only made the problem

worse.†† So the solution was a new

fan.†† The old one had a part number 102

200 11 23 (which means that the 190E 2.3 uses the same part) but the

replacement fan arrived as a 102 200 21 23.††

I tapped the same way on the new fan, and there was no noise. It was

around $75, and worked as advertised.†† I

found that this part was not readily available online; apparently this is not a

commonly replaced part.†† But I don't

know why, as I should think that many of these are replaced during front end

collisions.† Anyway, I should think that

dealers can get it without too much delay.

CLIMATE

CONTROL PUSHBUTTON UNIT (added November 2010)

The pushbutton unit has the circuitry that

tells everything else what to do.† It

tells the switchover valves to open and close various ports (which control the

various flaps and vents) based on the pushbutton and wheel settings as well as

the sensor data (ie interior temp sensor, feedback

potentiometer, evaporator temp sensor, compressor speed sensor, etc) and it

also controls the function of the air conditioner compressor.††† On our unit, we replaced it when the temp

wheel spun round and round.† Obviously

its ability to set the proper temperature is hindered when this happens.† Also, the pushbutton contacts can become

dirty,† and a

shot of contact cleaner can go a long way towards restoring functionality.† Also, it has been reported that the pins on

top of the control unit, as well as the corresponding plugs on the harness, can

become dirty (see photo below).†

Electrical contact cleaner should also be used on both of these areas. †††The circuit cards inside these units are

also subject to hairline cracks over time, and if you are so inclined, you may

want to look the circuit card†

over with a loupe to see if you can find the broken

connection.†

George Murphy at Performance Analysis in

If you find your unit needs replacing, beware

of just buying a replacement on eBay.††

The electronics changed over the model years, mostly in their ability to

control the compressor, and they are not interchangeable.††† My car, a 1985, calls for a unit numbered

201 830 03 85.††† Interestingly enough,† the unit I took out

of my car was a 201 830 05 85,

but best to use the correct number.†† It

is possible that these two numbers are considered interchangeable.

201

HEATER CORE - KABOOM!†† (added November 2010)

So I was driving home from work one night and

then I received The Call from Mrs C - car full of steam, a loud noise, carpets

soaked with hot coolant, blue jeans too.†

She quickly pulled over and got out.†

I arrived at just about the same time as the AAA tow truck, who brought

it home to our garage.† By the time I was

home, I had worked out in my head what had happened - a catastrophic failure of

the heater core. †As I found out later,

one of the plastic tanks along the side had cracked (see below).†† And I knew what I had to do:† dash removal, heater box removal, heater box

disassembly, and then put it all back together, but not before changing out

some parts which it would be wise to replace now that the tough parts to get at

can be accessed easily - specifically, the feedback potentiometer, its

accompanying vacuum element, and the fresh air flap vacuum element.†† The other two vacuum elements should also be

changed if more than ten years old - mine were about two years old, so I kept

them.† Dash, heater box and heater core

removal instructions below towards the bottom.††

Photo below shows exactly where the heat exchanger cratered.†† Some people believe that failures such as

this can be caused by using green coolant instead of Mercedes-Benz brand

coolant.† Why take the chance?† Always use MB coolant.† It is no more expensive than other coolant.

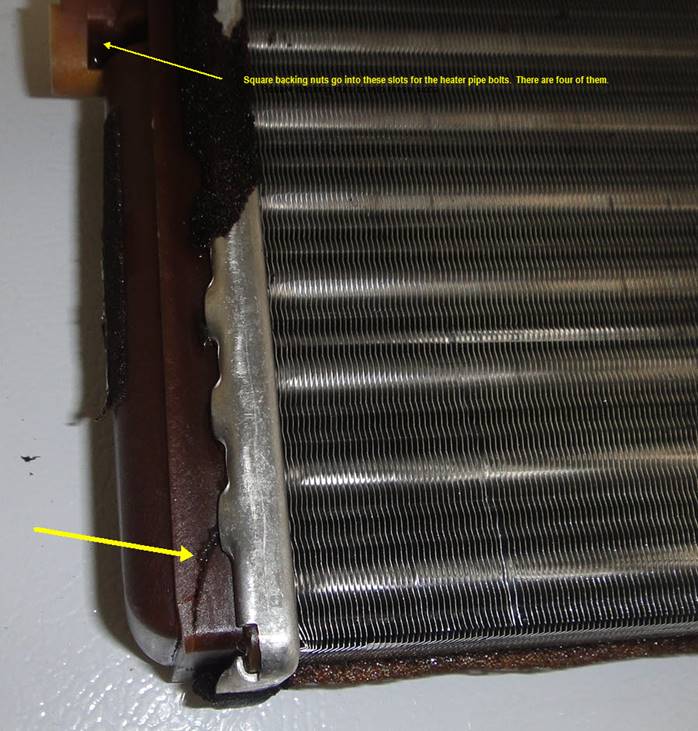

When removing the heater box from the car, I† had a panicked

moment when some square nuts came tumbling out onto the carpets, and I had no

idea where they came from.†† They were

square - very un-Mercedes - but I put them aside anyways.†† Mystery was solved a short time later when I

found out four of them were used to secure the two pipes to the heater

core.† New nuts and bolts come with the

heater core but I don't like the new bolts.††

More on that below.

INTERIOR

CABIN TEMPERATURE SENSOR

This is a great place to start.† If this sensor is not working properly, there

is no way the system will work right.† It

is located right next to the rear view mirror, and we are going to test it and

clean it of all the gunk and smoke† that has blown through it all these

years.† It has a two-wire plug and a hose

attached to it.† The hose goes down to

the aspirator blower, and we will test that below.† Pry out the light next to the rear view

mirror, and on my 1985 the way to remove the sensor is to reach in and slide

the U-shaped clip holding it in position towards the driver side.† Once the clip is out, then the small plastic

grille can be carefully pried out, freeing the sensor.†† Now test it with an ohmmeter.† 68F should yield 11.5 to 13.5k ohms, 77F

should yield 9.5k-10.5k, 86F should yield 7.5-8.5k ohms.†† Also, take a look inside the hole, and give

it a few blasts with some electrical contact cleaner.† Now test again with the meter.††† To reassemble, push on the wire and the

hose, and line up the sensor business end with the opening in the headliner and

push the plastic grille into place.† Then

secure with the U-shaped clip and replace the dome lamp.

INTERMITTENT BLOWER?

INTERMITTENT BLOWER?

If you find that your blower is working

intermittently, in the heat mode, it is a good chance that your auxiliary water

pump mounted on the inside fender well below the radiator bottle (see photo) is

old and/or broken and drawing too much current. This causes the ACC system to

shut down. To test for this condition, unplug the aux pump (a 2 pole connector

that clips next to the pump bracket) and see if the blower begins to function

normally. If this is the problem, then keep the pump unplugged until you are

able to replace it. If this is not done, the malfunctioning pump can damage the

IC's on the pushbutton unit. The aux pump is not a critical item; it only

serves to keep the hot water running through the heater core during heavy

traffic or when the engine is otherwise idling. I paid $118 for my replacement.

However, I replaced mine when it started to leak.

Sometimes you may experience a blown blower

fuse. Mercedes-Benz had a recall on some of the 190's, and it had to do with

the fact that some blowers needed more current than the fuse could handle. The

fix is to install a fuse bridge. If your fuse keeps blowing, call Mercedes-Benz

at their 800 roadside assistance number, and they will direct you to someone

who can look up online whether your car requires this service, and if it has

been done already.

TOO MUCH AIR CONDITIONING?

TOO MUCH AIR CONDITIONING?

Sometimes the compressor just won't shut off

while the system is operating. The first place to check is the fuse on the back

of the pushbutton unit. I provide detailed instructions below for removal of

this device. See the photo below for the exact location of this fuse.

TROUBLESHOOTING THE HEATER VALVE

If your symptom is too much heat, a

good place to start is the heater valve located under the leaf trap between the

2 firewalls on the passenger side, just behind the battery. It is a simple

vacuum-operated element which controls a gate that, when vacuum is applied,

shuts off the coolant flow on the return pipe of the heater box. Siphon off

some coolant, remove the black "leaf trap" that sits just underneath

the windshield, and find the valve. Pull off the vacuum pipe from its top,

loosen the 2 hoses from either side, and remove it. Check it for smooth

operation, and finally put the vacuum pump onto the element and see if it holds

the vacuum. If it doesn't, it's a $25 part. It might be a good idea to replace

it anyway; some owners have noticed that over time, the valve leaks a small

amount of coolant.† Also, this valve can

fail internally, although the vacuum part is ok.†† This will keep the heat out of the car until

the problem can be completely diagnosed and rectified.†† If it is in the middle of summer and your

only concern is keeping heat out of your car, you can either apply vacuum

directly to the valve, thus keeping it closed, or you can bypass it entirely by

either blocking the flow somehow, or else run the hose in such a way that it

bypasses the heater core entirely.†† So,

in summary, no vacuum=full heat, vacuum=closed.

So, now that you have access to the valve,

check for proper vacuum going into the valve by plugging your vacuum pump

directly onto the dark red pipe which fits onto the heater valve.† Start the car and set the system to maximum

cold. Is there vacuum present? There should be, and if there isn't, then it's

time to dig deeper into the system.††

Best to check the integrity of the pipe from the switchover valves., and be aware that there is a 2" rubber hose

joining the 2 pieces of dark red pipe between the heater valve and the

switchover valve.

CHECKING FOR VACUUM LEAKS

The center of the whole system are the

switchover valves. There are two of them, and all of the Tempmatic

vacuum pipes connected to the vacuum elements terminate at either one or the

other. This makes it an ideal spot to quickly check the whole system for vacuum

leaks, which can occur due to heat or age.

Accessing the switchover valves is done by

removing the glove box, the right hand side vent, and the aspirator blower, in

that order. To remove the glove box, first pull out and unhook the small clear

rectangular light. Along the edge of the box are seven black 2-piece plugs

which hold the box in place and can be pried up, one part at a time. The box

then comes out. The right side air vent is removed by grabbing on to the grille

with a pair of needle nose pliers wrapped in a rag. Give it a tug, and it comes

right out. The frame comes out once the four plastic prongs behind the grill

are pried slightly away, allowing it to be pulled towards you. You may find

that the frame comes out easier if you work at it from behind by removing the

stereo speaker just above it.

Now we test and remove the aspirator blower.

It is cylindrical, and sits directly behind the right air vent. Its function is

to suck air past the interior air temperature sensor located in the headliner,

thus facilitating a quick response from the ACC system. If the symptom of your

system is a slow response time, this is a good place to check. There are two

ways to test the aspirator blower. The first way it to turn the key on, and

light a match in the car. Blow it out, and put the smoking match up to the

sensor, in the headliner. Does the smoke get drawn in? Then it's ok. Or, you

can also turn on the ignition and hear it run and see the fan blades spinning.

Also, sometimes the pipe leading from the blower to the sensor can disintegrate

due to age, so make sure it's in one piece. (Try blowing through it.) Once

you've checked it all out, take it out by lifting it up from its securing clip,

and unplugging the electrical connector. Work the pipe loose, and take the

blower out.

Now we maneuver the two switchover valves

into a more convenient spot for testing purposes. They clip into place to the

black bar in two places, and on my car they were also secured by means of a

black nylon tie. Cut the tie, unclip the valves, and gently take them out of

the glove box, leaving them connected.

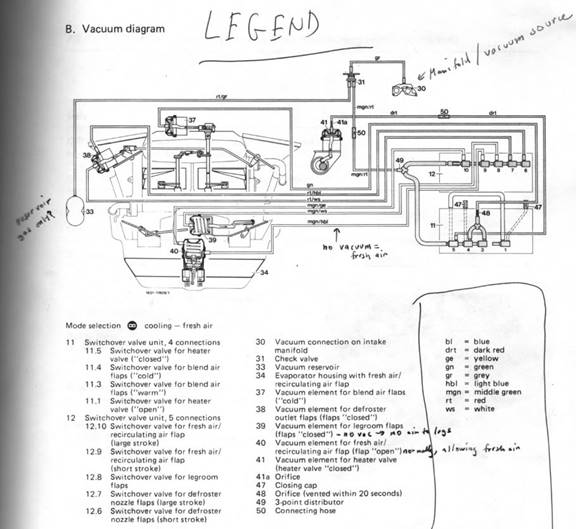

Finally, time to begin the vacuum leak

testing process. Here is a vacuum diagram to help you understand the flow:

Testing for proper engine vacuum - Notice

that vacuum comes from the manifold (or vacuum pump in the 190D) to both

switchover valve inputs through a rubber Y. There should always be vacuum at

this Y, as long as the engine is running. So let's test to see if it's still

the case. Separate the pipe from the Y, and plug the pipe into your vacuum

pump. Start the engine. Vacuum ok? If not, look for a vacuum leak between the Y

and the manifold. When done, put it all back together. Switch off the engine. A

good place to start is at the rubber hose that joins two pieces of pipe between

the manifold / vacuum pump and the Y at the switchover valve.

Now we can test the pipes and associated

elements on the 4 port switchover valve. In the MB ACC Tempmatic

book this device is known as #11.

Port 5, on the left, has a dark red pipe, and

goes to the heater valve element. Pull the pipe off the switchover valve, put

the pipe on your vacuum pump, draw it down and see if it holds vacuum. If not,

follow the line and find the leak. It's a good practice to use a new rubber

elbow to connect the pipe to the switchover valve. These parts are cheap and

can prevent vacuum leaks later.

Ports 4 and 3, next to it, control vacuum to

the blend air flap element. Note that they are connected together with a rubber

Y. Port 4 supplies vacuum when cold is selected, and port 3 vents to atmosphere

when more heat is needed. The switchover valve receives its instructions from

the pushbutton unit. To test, remove the green pipe from the Y, and plug it

into the vacuum pump. Apply vacuum and see if it holds. If not, you need to

find the leak. It may be a bad element on top of the heater box, or a bad

rubber elbow on the element. You may need to remove the dashboard to trace the

leak unfortunately. Reassemble the Y when done.

Now we test the pipes and elements connected

to the 5 port switchover valve. In the ACC manual this device is known as #12.

Ports 10 and 9 both go to the fresh

air/recirculating flap underneath the heater case. Unplug each in turn and

connect to the vacuum pump. See if they both hold vacuum. They should. It is a

2 stage element, meaning that one pipe is for a short stroke and the other pipe

is for the long stroke.

Port 8 has a middle green / white pipe which goes

to the legroom flaps element underneath the heater case but above the fresh air

vacuum element. Remove the pipe, plug it into the vacuum pump and see if it

holds vacuum. It should.

Ports 7 and 6, on the right side of the #12

switchover valve, both go to the defroster outlet flaps element on the left

side of the heater case. This is another 2 stage element, and both should hold

vacuum.

REMOVING THE LEGROOM FLAP AND FRESH AIR /

RECIRCULATING AIR VACUUM ELEMENTS

If you find that a vacuum element is no longer

holding vacuum, you may elect to repair the old one, or just purchase a new

one. George M. sells the rubber inserts, along with instructions on how to

change them. It does not take long once the elements are out of the car.†††

Both the legroom flaps element and the fresh

air / recirculating air element are located behind the radio, but the center

console must come out first. It sounds more difficult than it is; first remove

the center vents using a needlenose pliers surrounded

by a rag, and then, after closing the vents first, remove the two screws

holding it up to the dash.† Use an offset

screwdriver for this, or you can also use short screwdriver sockets.† Then remove the two screws holding it to the

transmission tunnel on either side. Remove the panel under the steering wheel,

and then the whole unit should just move forward. Unplug the connectors to the

rocker switch, the fan switch, the two pushbutton unit connectors, the two

ashtray connectors, and anything else you see in the way, including the radio.

Move the center console out of the way so you can get to the two elements. It

is easy to remove the elements once you know the trick.

The legroom flap one needs to come out first.

The secret is that they don't just turn out. With a flashlight, look at the

bottom of the element where the bayonet-style fitting sits in the metal

bracket. One of the three bayonet catches is longer than the others, and the

extra length is a piece of flexible plastic which pops into a hole in the metal

bracket once the element is oriented correctly. This little plastic button

keeps the element from twisting or shaking out of the bracket. Knowing this,

the easiest way to remove the element is to locate the plastic button sticking

up, push it in, and turn the element out. Pull up on it the whole time to help

the button out of the hole. Once it is out of its bracket, remove the plastic

cover over the end of the actuator rod. Using a small screwdriver, gently pry

towards you the metal rod going to the legroom flaps. The actuator rod should

then just come out. Maneuver the element out of the car.

The fresh air flap element secures to its

bracket in the same way. The bad news is that the plastic button is on the

hardest to access part of the bracket. I was able to push the little button in

with my finger and pull up with the other hand. Remove the two vacuum pipes,

noting that the green/yellow pipe is on top. The actuator rod is held into the

door by a small plastic fitting. Give it a quick push and it should pop out.†† Once both elements were out, the first thing

I did was to file down the button to half its size so that next time they would

come out without having to worry about finding the buttons.† I found that it is a good idea to test and

visually confirm proper operation of the vacuum elements before putting the

center console back into place.†† It is

possible to hook up all the cables and then just not screw it up into place and

watch the elements open and close as the various buttons are pressed.

THE

DEFROSTER VENT VACUUM ELEMENT

First of all, what is the function of this

part?†† If you were to remove the

steering wheel and instrument cluster and watch it work (and this is what I

did), this is what it would do: if you select one of the console buttons that

points air towards the windshield, the element should move in one direction,

and vice versa.† All this does is route

the air up or down.† You can troubleshoot

the defroster vacuum element a couple of different ways.† Firstly, if you have access to the switchover

valves, see if both parts of it are holding vacuum.† If not, then the rubber element has

failed.† You can also check it by

removing the instrument cluster and viewing its operation as indicated

above.††

If you determine that the defroster vacuum

element is bad, the first step is to get a replacement element.†† Note that there are two different varieties

of vacuum element (see photo below).† The

pink and green one is the earlier version, part number 201 800 05 75, and the

black flat oval one is the later version, part number 000 800 87 75.† The later one is not a replacement for the

earlier one, so if you need the earlier one, donít buy the later one and expect

it to fit.†† In my particular case, I

found that the VIN cutoff number wasnít accurate; Mercedes claims I needed the

newer style, while only the earlier style with the round bayonet mount will fit

in the car.†† See the photo below of the

two varieties.

To change it, remove the steering wheel

(caution if your car has an airbag) and then the instrument cluster. ††In order to remove the instrument cluster, it

is first necessary to unhook the speedometer cable, and that isnít always so

easy.† Try sliding out the cluster an

inch or two and then try to slide your hand back there and unscrew it.† It is easier to unscrew it than to screw it

back on.† I found the easiest way to

screw it back on when the time comes is to remove the bottom panel by the

pedals, and then work your hand up and behind the cluster.† A bit of grease on the cable and threads

helps a lot, and also line up the cable with the speedo before giving the

cluster a push into a closer position.†

OK, so once the steering wheel and instrument cluster are out of the

way, the rest is easy.† Look straight

ahead and you canít miss it.† Remove the

element, taking care not to lose the little white plastic connector that fits

on the end of the rod, and turn it out while prying it slightly away from the

mount to override the little plastic button which prevents it from unscrewing

on its own.†† As long as you are at it,

replace the rubber vacuum pieces which connect the elements to the tubes.† If they are old, they can crack or lose their

elasticity and create vacuum leaks of their own

TESTING THE SWITCHOVER VALVES

The switchover valves consist of several

small vacuum elements which open and close via separate electrical contacts

upon the command from the pushbutton unit, which gets its command from various

electronic sensors. Switchover valves can fail electrically as well as

mechanically. Judging by the fact that Fletcher Jones had 3 of the new-style

switchover valves in stock when I called (more on the new-style switchover

valves later), I'd bet that they replace these things quite regularly.

Now, this time around, instead of testing the

pipes, we will test the ports to see if they are providing proper vacuum. Note

that if a fault is detected here, it does not necessarily mean that the

switchover valves are bad, although the part does become suspect. Starting with

the forward switchover valve, the 4 port, #11:

Let's go back to port 5, on the front 4-port.

Remove the dark red pipe, and plug your vacuum pump onto the port. Start the

car, and turn the temp wheel to Min, meaning maximum cold. Your gauge should

register vacuum, as this will close the heater valve. If this doesn't happen,

make a note of it and put the pipe back on. Below is a picture of the new style

switchover valve, courtesy of James Meyers. Notice how all the ports on the

other two valves are incorporated into this single unit.

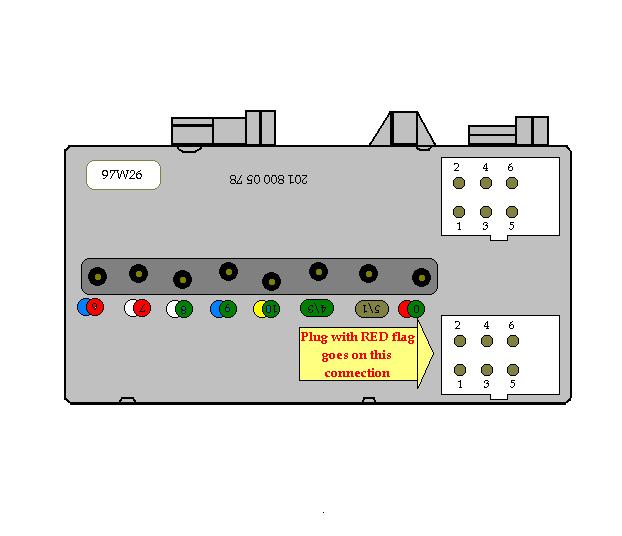

And also, courtesy of James, is a diagram of

how to plug in the two identical connectors. There are no markings on the

switchover valve, so this picture will tell you how to do it.

THE DREADED 190 CLICKING BEHIND THE GLOVE

BOX NOISE

Ports 4 and 3 as mentioned earlier work

together to alternately supply and vent vacuum to control the blend air flaps

to regulate temperature. This is the source of the clicking behind the glove

box which has plagued so many of us 190 owners, as the system electronics

rapidly try to set the blend air flaps to the correct spot. This noise is not

indicative of a bad switchover valve, however. It is much more likely that the

associated electronics are faulty, but I will elaborate more on this below. To

test the switchover valve, remove the Y from port 4, and see if vacuum is

present at the port after setting the AC to maximum cold. If it's ok, then plug

the gauge into port 3, and set the temp to cold. Pump in some vacuum. It should

hold. Then swing the temp dial to max heat, and see if the vacuum is vented as

the blend air flaps move accordingly. If this doesn't happen, make a note and

put it back together.

On my car, I noticed that ports 4 and 3

became very hot once upon a time, as there was burn marks surrounding the area

where the pipes plug in. Nothing concrete in that, but very suspicious!

Now let's test the rear switchover valve, the

5-port. Select maximum heat and start the car:

Ports 9 and 10 should receive vacuum when the

"0" is selected;

Port 8 should receive vacuum when the third

from left button (2 white arrows) is selected;

Ports 7 and 6 should receive vacuum when the

second from right (center vent) button is selected.

The electrical portion of the switchover

valves can also be tested, but the ACC manual shows how to do it from the

pushbutton unit connectors. It's a good idea to do it this way, as removing and

then plugging in the connectors sometimes has the ability to restore a dirty

connection. You may even want to spray the contacts with electrical contact

cleaner.

To access the pushbutton unit connectors, we

first need to drop the center console. Remove the two center vents using a rag

and needlenose pliers, and then loosen the two

Phillips screws holding the console up to the dash. Close the vent so you don't

lose a screw into the console. Once the screws are out, the whole unit pivots

down a couple of inches, and the 2 plugs are clearly visible on either side on

the back of the pushbutton unit.

To test the 4-port switchover valve in front,

we check for the presence of a short or open circuit, and it is done from the

left hand connector at the pushbutton unit. There should be 60 - 70 ohms

between contacts. Remove the left side connector. Connect the negative ohmmeter

probe to a good ground (there's a metal nut in the area) ,

and test holes 1, 2, and 4 for either a short or an open circuit, which would

indicate a definite problem with that part. (ACC manual, pp. 83.11-039/3)

The 5-port switchover valve can be checked by

using the pushbutton unit right hand connector. With the valve plugged in,

connect the negative ohmmeter probe to a good ground, and test holes 1, 2, 3,

5, and 6 for either a short or an open circuit, which would indicate a problem

with that part. (ACC manual, pp. 83.11-039/4)

The good news is that if you determine that

your switchover valves are not functioning properly, whether there is an

electrical problem and / or the vacuum doesn't seem to be routing properly,

Mercedes-Benz has redesigned the two parts into one unit. This simpler design

does not require the use of the two rubber Y's, and thus there are less parts

to leak vacuum. I have also noticed that they do not click quite as loud. I

would imagine it is also more reliable on the inside too.

TESTING THE FEEDBACK POTENTIOMETER

The final component this article will test is the

feedback potentiometer, which is an electronic device that lets the pushbutton

electrical control unit know exactly where the blend air flaps are. Part number

for the 1984 and 1985 cars is A 2018210260.†

I do not know if the part changes for later cars.† It may not.†

Like any electromechanical device, this component is prone to wearing

out, getting dirty contacts, or going out of adjustment.

The final component this article will test is the

feedback potentiometer, which is an electronic device that lets the pushbutton

electrical control unit know exactly where the blend air flaps are. Part number

for the 1984 and 1985 cars is A 2018210260.†

I do not know if the part changes for later cars.† It may not.†

Like any electromechanical device, this component is prone to wearing

out, getting dirty contacts, or going out of adjustment.

It is difficult to access, but can be tested

via its wires from within the glove box. Locate the 3 wire connector which can

be found in the dash around the right side of the center vents. Pierce the

center green and red wire with the + probe of your voltmeter, and secure the

other one to a GOOD ground. A bad ground wire will yield lower and inaccurate

voltage readings., so make sure you've got it right.

(My first attempt at adjusting my potentiometer was thwarted by a bad ground.)

Start the engine, select the button for the center air vents, and set the temp

wheel to the minimum, meaning maximum cold. You should read 4.4 - 4.5 DC volts

for cars up to 1986, and 2.4 - 2.7 volts for cars 1987 on. Turn the temp dial

back and forth, and watch the digital readout. If at any time there is an open

circuit, then the the pot is bad. If the readout is

in any way less than perfectly smooth, then it is dirty or defective. Any

problem in this area is more than likely going to result in the clicking noise

over at the switchover valve #11 as the erratic electronic readings give the

vacuum elements mixed and confusing signals. The picture below shows the

feedback potentiometer along with the associated vacuum element.

The vacuum element shown in the photo is an

example of one way the part can go bad; note how the metal rod can flex to one

side and can no longer accurately control the feedback potentiometer. The

rubber in the element can also disintegrate due to heat or age.

If the feedback potentiometer is out of the

car, an ohmmeter is a good way to test how well it operates.† Smooth readings across the range is key.† In the photo below, I opened it up by

carefully prying the three plastic tabs.†

The cover lifted off to reveal the pot. I

gave it a good spray of electrical contact cleaner, and then measured the

resistance across the three wires, two at a time, when the lever is at the far

left, and again when it is at the far right.†

Resistance ranges were as follows:

Red

and blue: 1k - 5k ohms

Blue

and brown: 11 ohms to 4.2 - 4.7k ohms

Brown

and red: 5k - 5k ohms

Your

readings should be similar, although probably not exactly like mine, and

remember smooth across the scale.†† Keep

in mind that the movement range of the lever is adjusted with a screwdriver

once it is in place on the heater box. See the voltages listed above in the

Testing section. †A non-digital voltmeter

may work better to measure smoothness.††

On a digital meter, I had better results going from high to low. †

By

the way, this test can also be done while the pot is still in the car.† The lever is controlled by a vacuum element;

disconnect the top of the ĎTí on switchover valve ports 3 and 4.† Using a Mityvac, slowly suck the air

out.† This should move the feedback

potentiometer through its range.†

The

pot looks pretty basic; if you were in a pinch, I bet you could take the pot

out of this housing, find a similar one on eBay, and put it back together.††

If there is a problem with your feedback

potentiometer, it will be necessary to remove the dashboard, steering wheel,

and instrument cluster in order to change it. It is a time consuming job, but

not an overwhelming one if taken step by step. The good news is that it is a

good opportunity to change that cracked console. New dashboards can be had for

about $350 or so.†† Give yourself about a

week for good measure to take your time and do it right.† Figure a day to get the dash off, a few days

to get the parts (once you know what you need), and then a day or two to get it

all back together.†† The 201 chassis

manual gives thorough instructions on how to do this step-by-step. It is not

difficult but takes a while.† Also, see

my take on how to get it off below.

If your system seems to be getting erratic or

erroneous signals, the switchover valves just are not doing what they should,

and your feedback potentiometer checks out OK, your problem may be in the

pushbutton unit. Frequently they develop cracks in the printed circuit boards.

You may be able to determine if this is your situation by removing the box and

also the bottom. The plug it back in, and turn on the system. See if you can

get different things to happen to the ACC system while you are gently flexing

the PC board with your fingers. If this happens, then you may be able to spot

the loose solder joint which can be resoldered with a

low voltage soldering iron and some rosin core solder. Alternatively, George

Murphy can test these units inexpensively, and if there's a problem with it, he

sells rebuilt exchange units.

NOVEMBER

2010 - DASH REMOVAL - Not difficult,

but lots of little projects and parts, so get organized.† My method is to have a box of ziplock bags handy, along with some Post-It Notes.†† All screws in each 'project' get put in a

bag with a note.†† Here we go:

Steering Wheel - Non airbag cars: pry out the

center logo, using a small screwdriver.†

See the big allen

bolt in the center?† Mark the wheel and

steering rack with a sharpie pen so you can line the two up once the wheel goes

back on.† Using a big allen

socket on a eighteen inch breaker bar, or longer, remove the bolt holding the

wheel in place.††† Give it a really big

'snap'.† If you try gradual pressure, you

will never get it out.† Just one big fast

push should do it.†† Airbag cars:† I have no experience with this.† You are on your own.† But be careful.†

Four air vents - with each one, use a pliers,

protected by a rag, and yank them out.††

These get brittle with age and are not expensive if you need to replace

them.

Headlight knob - Using same pliers and rag,

yank off the knob.† Undo underlying nut,

and then put plate, knob and nut in a baggie.

Bottom panels - Remove screws holding them up

from under the instrument console and glove box.† Easy.

Ignition trim ring - Pry off using a small

screwdriver.†† Piece of cake.

Steering column surround - Once the steering

wheel is off, there are some bolts surrounding the big bolt which should come

out.† Then the turn signal switch and

cruise control switch should be removed.†

They can be left hanging in place.††

I did this because the first time I removed the dash, I inadvertently

destroyed the cruise control switch as I wrestled it into place.† Not again.

Glove box: Using a small screwdriver,

separate the two little plastic grommets that go around the inside of the glove

box.† Take out the top bit, then pry out

the bottom bit.† Then pry out the little

light and disconnect.† Unscrew the two

screws holding the latch in place.†

Everything in the baggie. Slide out the box.

Dash speakers - remove the two small screws

holding the covers in place.† Then

unscrew the speakers, remove the wires.†

See those bolts in each side?†

They hold the dash in place.† We

will get to them later.

Drivers side vent fascia - Carefully pry out

the little switch for the interior light.†

Unplug.† Then carefully pry up on

the four plastic tangs holding the part into the dash.† Remove.

Center console - Using an offset or really

short screwdriver, remove the two small screws in the center vent fascia

holding it up.† Then remove the two

screws below, on either side. Drop the console down, and disconnect the two multipin connectors on the climate control unit.† Unplug the connector on the fan switch.† Unplug the radio connections.† Then take the whole thing out of the car.

Center vent fascia - See photo below.† Using an appropriate allen wrench, loosen the bolt on the little lever

which secures it to the heater box.†† Pry

out the switches, and then remove the two additional upper screws holding it in

place.†† Remove.

Instrument cluster - this is the part which

is hardest.† Step 1 is to unhook the

speedo cable.† Carefully pry out the

cluster, and try to get the cable off either by going in through the side, or

by going up from below.† It is possible

to gain a little more space behind the instrument cluster by first unmounting

the headlight switch and using that space to jam your hand in.†† Then unscrew the knurled nut, and once this

is done, it comes out a little more.†

Snap a photo of the different wires, and where they go.

Pillar panels - with the front door open,

pull back the weather stripping around the pillars going from the roof down

along the windshield to the dash.†

Carefully work them off.† They are

held in place by clips.† Once removed,

put the weatherstripping temporarily back in

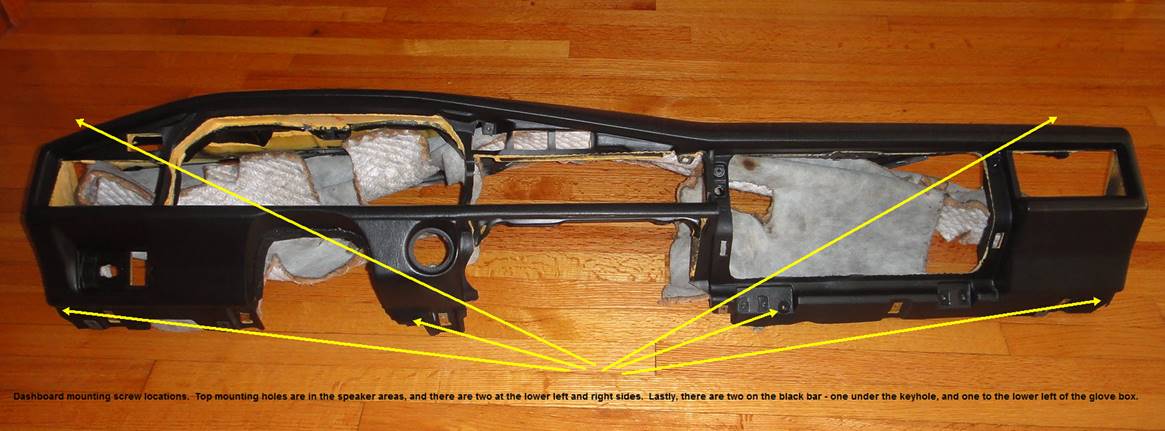

place.†† As you can see in the photo

below, the pillar needs to be pulled straight back.† The clip in the picture below contains the

plastic remnants of my pillar panel which was undoubtedly caused by pulling the

panel in the wrong direction.†† Next time

it will go better.

The dash - Remove the bolt on the far left

and far right side.† On the left side, it

is near the headlight switch.† Remove the

two bolts in the front speaker areas, and then remove bolt holding dash below

glove box.† Also one more on underside holding

it to the big black bar, just below keyhole.††

At this point, it should just lift out.

DASHBOARD

REINSTALLATION - Fairly

straightforward, but there are a few things to keep in mind.†† I ended up doing everything exactly twice -

a part would go on, something would not be right, and off it would come and

then I put it back on.† Whenever this

happened, I made note of it, and I write about it below.

Probably best to replace the two foam square

surrounds on the top of the heater box.†

In Mercedes-eze, these are called a 'Sealing

Rubber Joint', part # A 201 835 00 98.†

My two replacements had to be ordered from

I found it easiest to put the dash into place

first, and then loosely secure it with the two side bolts.† Then I put in the top speaker bolts, and

lastly the two on the lower edge at the key and glove box.† Organize the wires by pulling all instrument

cluster wires out through the cluster opening.†

Organize the fiber optic wires.†† The function of the fiber optic wires is to

supply lighting to the three center vent fascia switches as well as the rear

cabin light switch to the left of the instrument cluster.†† The light source comes from bulbs in the

instrument cluster.† A good idea to

change these bulbs as long as they are accessible.†† They are cheap and don't last forever.††

Glove box - try trimming back some of the

insulation padding.† It makes it fit a

little easier.† Also, before you close it

up, make sure all the pipes are securely on the switchover valve ports.† I had to take mine out again because one

popped off, and I only found this out after everything was back together.†

Center Vent Fascia - This was the first item

I reinstalled.†† Before you install it,

make sure there are clips on the dash holes so the two screws have something to

grab onto.† Do not tighten the center allen bolt too tight, as this

would keep the vent from opening.† Keep

trying the vent as you tighten to get it just right.† Make sure the clips are on the dashboard

holes.† Mine was almost completely

installed before I discovered this.† Had

to take it off again.

Center console - don't forget to plug in the

cigarette lighter power plug and the little light for the ashtray.

Instrument cluster - Above I wrote about how

to get the speedo cable off the cluster.†

Upon reinstallation, I had another problem - they 'key' broke off the

big round multipin connector.† I was then stuck with the task of orienting

the plug correctly.† Using my ohmmeter, I

found the pin that controls the instrument lighting by measuring resistance and

turning the light dimmer rheostat.† The

corresponding pin on the plug (from the Electrical Troubleshooting Manual) was

#13.† I then lined the two up and I was

over that hurdle.†† Put a little grease

on the threads of the speedo cable.† It

makes it go on just a little bit easier.

After putting it all back together, I tested

the system, and something wasn't quite right.††

With the ac off (if bottom button pressed), the up arrow button worked

ok through the hot and cold, but the two up arrow buttons only gave me hot air

in the defroster vents.† So I then

pressed the center vent button, opened the center vent, and I had a mixture of

hot and cold.† I turned on the ac and

still had a center vent mixture of hot and cold.†† So I took the glovebox out again, and lo and

behold, the pipe had come off port #8.††

While port 8 is for the legroom flaps, and the system should work fine

without legroom flaps, it is the vacuum leak which caused the problem.† The same result could also come from a torn

legroom flap vacuum element.† Or any of

the elements.†† So always best to get out

your mityvac and take a look at those switchover

valves and make sure everything is connected and tight.†

HEATER

BOX REMOVAL - The good thing about

removing your own†

heater box is that once it is out, you can take a little time and

give it its first real cleaning in 20+ years.†

It comes apart easily, and all the accumulated smoke, dust, grime, etc

can be cleaned from the flaps and passageways.††

Removal of the dash is the first step.†

You should know that coolant goes into the heater core from the engine

on the left side and then goes back to the engine on the right side.† The core, even though broken, may or may not

be full of coolant at this point, so just be aware of that.

Plumbing - The manual calls for removing the

pipes first from the engine as well as a white retaining clip; however, I found

that my heater core came out once I removed the two pipes on either side of the

core (two bolts each, and then gently pry out the pipes).†† The white retaining clip comes out by gently

working a small screwdriver underneath each of the little plastic bits that go

into the holes.† I broke mine attempting

to get it out, and wouldn't you know it, the part is no longer available from

Mercedes.† So be gentle with it.† Also, as noted above in the photo of my

cracked heater core, there are four square backing nuts which secure the heater

pipe bolts into place.† New ones came

with my heater core.†

Cable Tie - Using a pliers, squeeze the black

cable tie on the left side of the box.†

Open the tie so the wires can come out.

Bolts - The heater box is held in place by

four bolts.† Two are at the very top, and

the other two are one the sides. †On the

left side, it is next to where the pipe goes through the firewall.† The manual calls for just loosening this

bolt, as the box slides up and out, but the box comes out easier if the nuts

are removed.†† There is a similar looking

bracket and bolt on the right hand side.†

Remove this bolt too.†† Pry off

the little plastic clip on the hose on the drivers

side.† (see the

lower right arrow below).† This clip

press fits into the two little holes.† It

is brittle, so beware.

Lower Vacuum lines - Underneath, remove the

vacuum lines from the vacuum element closest to you.† The one farthest back (fresh air /

recirculation flap) does not need to be disconnected.

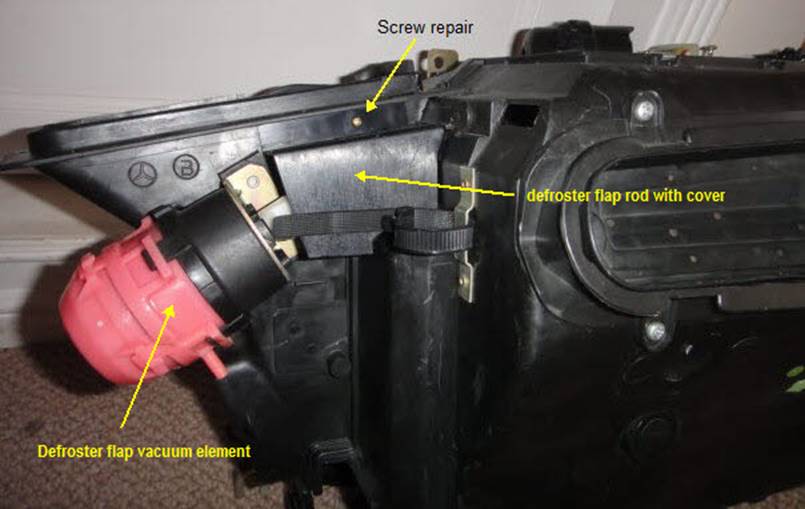

Defroster Flaps Element - Remove the vacuum

line supplying vacuum to the defroster elements.

Feedback potentiometer - On top of the case,

remove the vacuum line controlling the feedback potentiometer.† Also unplug the connector (see photo above of

feedback potentiometer and vacuum element).†

HEATER

CORE REMOVAL - Once the heater box if

out of the car, heater core removal is not difficult.†

Remove the defroster flap rod - See photo

below of the other side of the box.†

CAREFULLY bend the plastic cover upwards - it will break if you use too

much force, and then you have to repair it like I did - and remove the little

plastic rivet holding the element to the rod.†

Then pull out the rod from the defroster flaps.

Remove the lower legroom nozzles.† Be careful not to rotate the nozzles on the

rod, as this may put it out of adjustment.

Remove all the little silver clips holding

the two halves together.† Separate the

two halves, and then remove the screws holding the heater core frame into

place.† Note the position of the strips which† are stuck into

place and will need to be added to the new core.†

Now to replace - aftermarket or Mercedes-Benz

original?†† I was prepared to buy an

aftermarket, but found out that the original Mercedes part (A 002 835 54 01)

was available for just a few bucks more, so I went with that one.

Well, if you are with me this far, you

probably now have a few days to regroup while you are waiting for parts to

arrive.†† If you are looking for other

projects as long as the dash is out, how about cleaning all the ground points on

the firewall behind the light switch? †Many years of corrosion can set in and give

you electrical problems.† Better to take

a few moments and get ahead of them as long as they are readily accessible.†

HEATER

BOX REINSTALLATION

The troubleshooting manual calls for a piece

of cardboard which should be used between the car and the heater box to keep

the rubber condensation tray in place and interfering with the correct seating

of the heater box.† Also, before

installation, place the four square nuts into the heater core, and secure them

with a piece of tape.† There is no

getting them in once the heater is in place.††

Also, before installation, make sure any plugs have been removed from

the heater core.† Here is a photo of my

"factory spec" tool:†

"

"

Heater

pipe installation bolts - I found that

the original bolts were more 'pointy' and went in easier than the new

bolts.† See photo below.† It is a subtle difference, but I spent twenty

minutes and two bruised knuckles trying to get that new bolt in.† Finally I switched back to the original bolts,

and thirty seconds later I was done.†

There is just not enough of a point on the new ones, and the tips are

too fat to easily line up with the square nuts.

When refilling coolant, it is necessary for

the thermostat to be fully open to fill the heater core, so plan on a drive

around the block, refilling as necessary.†

And remember that coolant enters the core from the drivers

side and exits through the passenger side and heater valve.†

Finally, if you have found this article helpful, and

you are no longer either freezing cold or boiling hot while driving, you might

consider making a small donation via PayPal to go towards my next martini.†† Thanks!†

![]() †PayPalMe/JohnCacavas

†PayPalMe/JohnCacavas